Metal Engraving: Bridging Modern Innovations

Metal engraving, an age-old craft, has evolved significantly, seamlessly blending traditional techniques with modern innovations. At Talbot Walsh, we pride ourselves on our expertise in modern engraving methods, ensuring we meet diverse client needs. This article explores the importance and applications of various engraving methods, from the artistry of traditional techniques to the precision of laser technology.

A comprehensive understanding of these techniques is essential for selecting the appropriate method for specific projects in both jewellery design and industrial manufacturing. This analysis outlines the distinctions, advantages, and emerging trends within the field of metal engraving.

Key Takeaways

- Modern Methods: Laser engraving and computer-aided engraving offer speed and precision, making them popular in industries like jewellery and awards.

- Choosing the Right Method: Factors like project requirements, budget, and desired outcomes are crucial, making an understanding of modern methods essential.

Exploring Modern Metal Engraving Methods

Metal engraving boasts a rich heritage, blending traditional artistry with modern techniques essential for various industries, from jewellery to industrial hardware. Contemporary advancements, particularly laser engraving, offer unprecedented precision and efficiency.

This discussion elucidates the differences, benefits, and techniques associated with modern metal engraving methods, highlighting the artistry and technology that define the engraving industry.

Modern Metal Engraving Methods

Modern engraving methods, like laser engraving and CNC machining, have revolutionised the industry with advanced technologies that enhance precision and efficiency. These innovations allow artisans and manufacturers to achieve intricate designs with unparalleled accuracy, suitable for applications from jewellery creation to industrial signage.

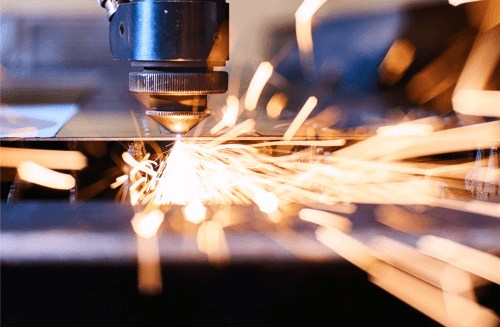

Laser Engraving

Laser engraving uses focused beams of light to etch designs onto metal surfaces with remarkable precision, making it a top choice for industrial and artistic applications. This non-contact method vaporises material at an extremely fine level, creating intricate details and minimising tool wear. Extensively applied in manufacturing, gift-making, and jewellery design, laser engraving enables finely detailed images, logos, or text. Its speed and efficiency enhance rapid production and customisation, meeting today’s market demands. Discover our laser engraving capabilities.

Computer-Aided Engraving

Computer-aided engraving has transformed the industry, allowing engravers to use CAD software for precise design transfers and intricate pattern execution. This integration ensures accurate replication of complex designs onto various materials, achieving high aesthetic and functional standards. In jewellery, detailed engravings on wedding bands and personalised gifts showcase the precision and detailing possible with CAD software. In industrial applications, manufacturers use these methods for branding and identification, demonstrating versatility and accuracy. Learn how computer-aided engraving can enhance your projects.

Comparison of Laser Engraving and Traditional Methods

Comparing laser engraving with traditional methods reveals significant differences in precision, speed, and cost-effectiveness, influencing the choice of the appropriate method for various applications. Laser engraving offers exceptional accuracy, producing intricate designs traditional methods find challenging. It operates faster, providing quicker turnaround times valuable in commercial settings. While laser engraving systems have higher initial setup costs, the long-term benefits often outweigh these investments. Laser engraving’s versatility across materials contrasts with traditional methods limited to specific surfaces.

Choosing the Right Engraving Method

Choosing the right engraving method is crucial for achieving desired outcomes. This requires understanding various techniques, quality standards, and application requirements. Evaluating these factors helps determine whether to use modern solutions like laser engraving, which offer enhanced precision and efficiency. The choice of material is critical, as specific methods yield better results on metals, while others suit wood or plastic. Considering project scale and intended use guides decision-making, ensuring method alignment with quality and durability goals. Contact us to discuss the best engraving method for your project.

Applications of Engraving in Various Industries

Engraving plays a crucial role across industries, creating intricate designs on jewellery and marking identification on tools and machinery, showcasing its versatility and importance. This craft enhances functionality and recovery in industrial manufacturing, with precision marking essential for quality control and traceability. In jewellery, laser engraving inscribes personalised messages on rings and pendants, ensuring distinctiveness. Awards and recognition use sandblasting for detailed plaques. Industrial engraving uses robust techniques like rotary engraving for durable, visible information on machinery components. Explore our industry-specific engraving solutions.

Future Trends in Metal Engraving

With advancing technology, the future of metal engraving will see significant developments, reshaping the industry with innovative techniques and enhanced quality standards. Laser technology evolution improves precision and creativity in design execution. Automation streamlines production workflows and reduces labour costs, enhancing efficiency and creating opportunities for intricate, customised designs. Engraving professionals will undertake a broader range of projects, expanding service offerings to meet changing consumer needs. Emerging technologies will make metal engraving more accessible and versatile than ever. Stay updated on the latest trends in engraving.

FAQs about Metal Engraving

Question: What are the different types of metal engraving methods?

Answer: The main types of metal engraving methods are laser engraving, CNC machining, and electrochemical etching. Each method has its own advantages and is suitable for different applications.

Question: Which engraving method is best for intricate designs?

Answer: Laser engraving is often considered the best for intricate designs due to its high precision and ability to create fine details without compromising the material’s integrity.

Question: How do I choose the right engraving method for my project?

Answer: Choosing the right engraving method depends on factors like project requirements, budget, material, and desired outcomes. Consulting with an expert can help you make an informed decision. Contact us for personalised advice.

Question: Can engraving be done on all types of metals?

Answer: Most metals can be engraved, including aluminium, brass, stainless steel, and more. The choice of metal and the engraving method will depend on the specific requirements of the project.

Question: What is the difference between traditional and modern engraving methods?

Answer: Traditional engraving methods, like hand engraving, involve manual tools and craftsmanship, while modern methods, like laser engraving, use advanced technology for precision and efficiency. Both have unique advantages depending on the application.